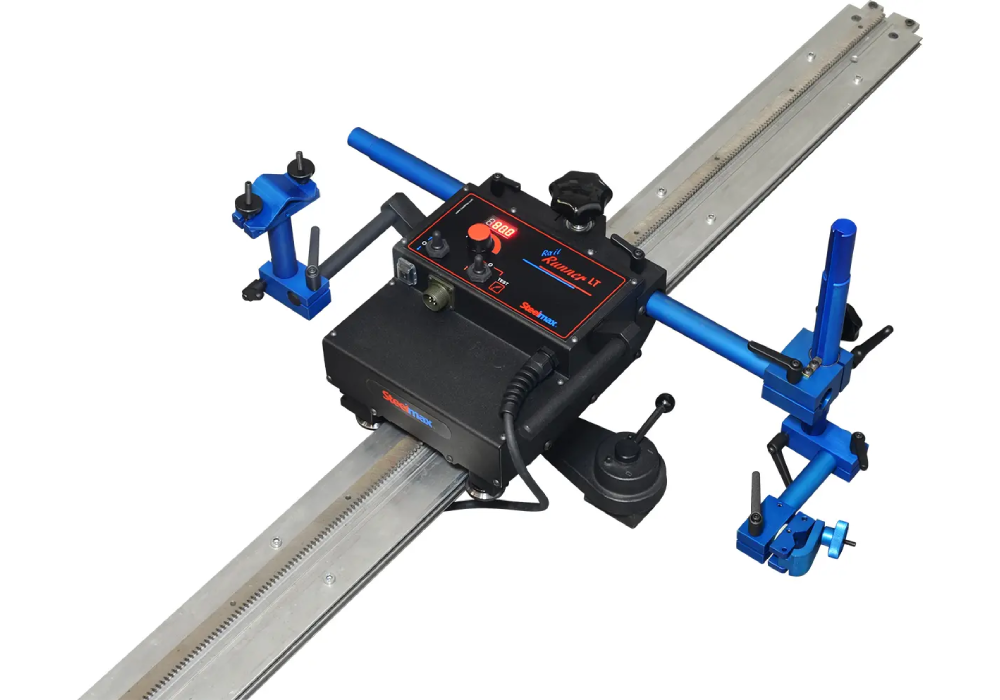

The Steelmax Rail Runner LT is a digitally controlled rail mounted travel carriage designed for the mechanization of welding and thermal cutting processes. Mechanized control of the welding or cutting torch allows continuous welding or cutting, increasing operating factor and deposition rates in welding applications. The Rail Runner LT features a rack and pinion drive system with electronic speed control that produces weld bead geometry that is exact to your required specifications, reducing costly over welding and minimizing filler metal usage.

The Rail Runner LT can be used with semi-flexible rail for plate and tank applications with a minimum diameter of 32 ft (10 m) and can be adapted to ring rails for pipe and tube applications.

Standard ring rails are available for tube diameters from 8” (200 mm) up to 10 ft (3 m). Custom rolled rails can be used for tube diameters between 10 ft (3 m) and 32 ft (10 m).

An optional vacuum system allows the rails to attach to non-ferrous surfaces such as stainless steel and aluminum.

The Rail Runner LT is an economical system for a wide range of welding and cutting applications on flat or curved plate, tube and pipe.

Applications: Trailer manufacturing, truck tanks, oil tanks, water storage tanks, pressure vessels, bridge girders, structural steel, structural towers, panel welding, transformers, shipyards, and any application demanding long continuous welds.

Arc Runner’s micro processor allows for development, storage and reproduction of up to 40 different welding programs for various joint configurations and multi-pass, multi-layer welds. Once an optimum weld procedure is developed, stored and programmed, Arc Runner will repeat it over and over again.

Standard Features

· Compact, lightweight design

· Closed-loop encoder insures accurate speed control

· Rack and pinion drive

· Digital LED display for pre-setting travel speed

· Automatic arc on/off initiates welding and travel simultaneously

· Suitable for a variety of circumferential and irregular surface applications down to a minimum diameter of 8″ (200 mm)

o Ring rails for diameters from 8″ OD up to 10 ft OD

o Custom rolled rails for diameters from 10 ft OD up to 32 ft OD

o Semi-flexible rails can be bent to a minimum radius of 16ft without permanent deformation

· Gear-driven cross slide for precise torch adjustment

· Application-specific accessory kits for oxy-fuel, plasma, MIG/MAG and SAW processes

Specifications and Capacities

| Voltage | 115 - 230V 50 - 60 Hz | |

| Power | 66 Watts | |

| Rail options for round tube & pipe | Ring rails | 8" OD to 10' OD (200 mm to 3m OD) |

| Custom rolled rail | 10' OD up to 32' OD (3m to 10m OD) | |

| Semi-flexible rail | Minimum Curvature Radius of 16' (5m) | |

| Torch types | Oxy-fuel, plasma, MIG/MAG, SAW | |

| Torch diameter | Oxy-fuel | up to 1-3/8" (35 mm) |

| Plasma, SAW | up to 1-3/8" (35 mm) | |

| MIG/MAG | 5/8" - 7/8" (16 - 22 mm) | |

| Horizontal pulling force | 67.5 lbs | |

| Vertical pulling force | 45 lbs | |

| Horizontal speed range | 4 - 80 in/min (10 - 200 mm/min) | |

| Vertical speed range | 4 - 80 in/min (10 - 200 mm/min) | |

| Wight | 22 Lbs (10 Kg) | |

| Part number | SM-WC-RR-LT |