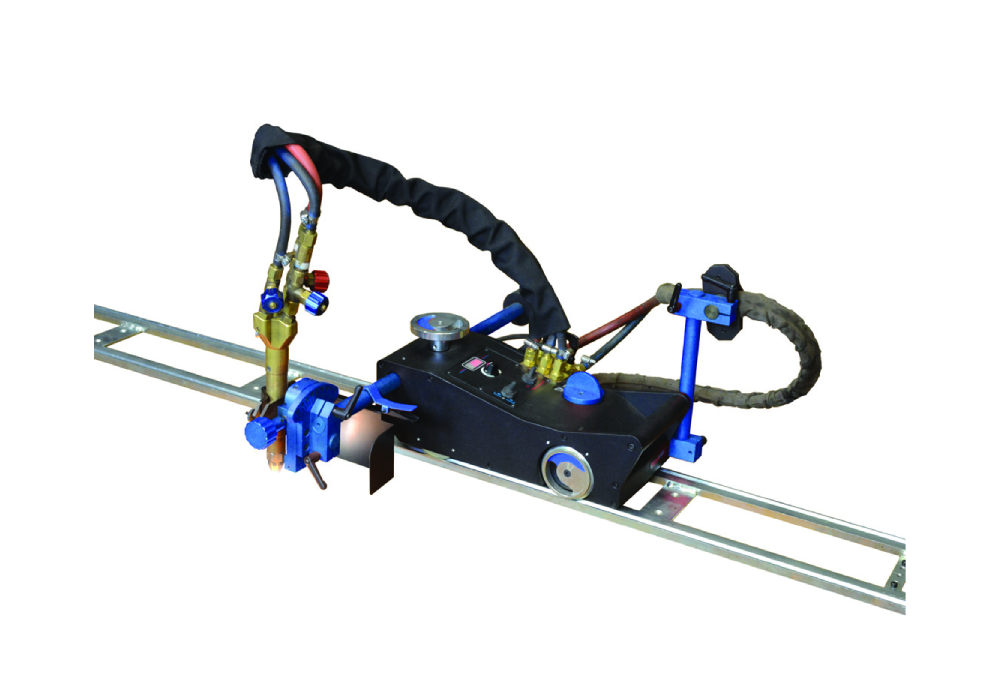

The Steelmax® Torch Runner is a state-of-the-art, digitally controlled track torch which maintains precise and stable travel speeds that produce accurate cuts and bevels with oxy-fuel or plasma. The machine can be used on any standard 6″ V-grooved track. Plate cutting and weld preparation can now be done with a high degree of precision. Quality cuts and bevels produced with Torch Runner reduce fit-up and grinding time and lay the foundation for a high quality weld.

The Torch Runner is available in two versions: a standard version for oxy-fuel cutting applications (up to 59 ipm) and a high speed version for plasma cutting applications (up to 118 ipm).

Standard Features

· 1-3/8″ (35 mm) Machine Barrel Torch Holder with precise angle setting up to 45 degrees

· Rigid heat-proof design

· Advanced Speed Control with electronic closed loop feedback for stable speed regulation

· LED Display with readout of actual and preset speed

· Two-wheel drive with braking

· Free wheel clutch system features rapid disengagement of drive mechanism for repositioning

· Interconnecting rails for long cuts and bevels

· Optional gas manifolds for two or three hose torches

· Optional circle cutting attachment

Specifications and Capacities

| Part Number | SM-WC-TR; SM-WC-TR-PLASMA |

| Power Supply | 115-230V / 50-60 Hz |

| Travel Speeds | 0-59 IPM (0-150 CPM); 0-118 IPM (0-292 CPM) |

| Dimensions (LxWxH) | 16-13/16? (18-5/8?) x 7-7/16? (25-13/16?) x 7-1/16? 427 mm (473) x 189 mm (655) x 180 mm |

| Weight | 37 lbs (16.8 kg) |